Discover Gainwell's Vietnam Manufacturing Hub

Premium hotel furniture powered by China-based engineering and Vietnam’s efficient manufacturing, delivered with reliable and scalable supply capability.

Why Vietnam for Hotel Furniture Manufacturing

Vietnam offers a stable manufacturing environment, an efficient cost structure and export-oriented policies, making it a strategic base for global hospitality projects. Gainwell leverages these advantages with a dual-factory presence.

Strategic Advantages of Vietnam

Gateway to Asia Pacific

Convenient access to key markets in Asia Pacific and the Middle East with well-developed seaports and logistics routes.

Policy & Cost Advantages

Favorable investment and export policies, combined with efficient manufacturing cost management, support long-term production for large hotel rollouts.

Growing Furniture Industry

A mature furniture industry ecosystem with an experienced workforce and well-developed supporting industries, ideal for complex hospitality projects.

China + Vietnam Dual Advantage

Gainwell combines China’s strong engineering and project management capabilities with Vietnam’s policy support and cost-efficient manufacturing to create a resilient, competitive solution for global hotel brands.

China: Design & Engineering

• In-house design and engineering teams

• Strong experience with global hotel brand standards

• Fast technical support and value engineering

• Mature supply chain for hardware and materials

Vietnam: Policy & Crafting

• Enjoys local investment incentives and export-oriented policies

• Competitive labor costs and stable manufacturing environment

• Strategic location for Asia Pacific, Middle East and beyond

• Flexible production for both volume and bespoke projects

Benefits for Our Clients

• Optimized total cost without compromising quality

• Diversified production base for greater supply chain stability

• Shorter lead times and more flexible delivery solutions

• One team coordinating across China and Vietnam for you

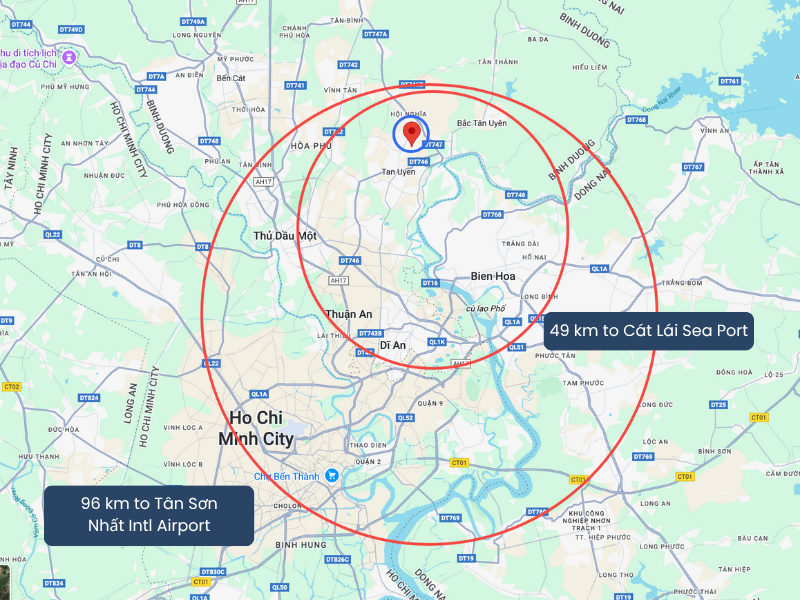

LEHOME (BINK KHUNGAN, BINH DONG)

Our established Vietnam manufacturing hub has a proven track record of delivering premium hotel furniture to luxury brands worldwide.

600+

Skilled Craftsmen

50000 m²

Factory Area

49 km

To Cát Lái Sea Port

96 km

To Tân Sơn Nhất Intl Airport

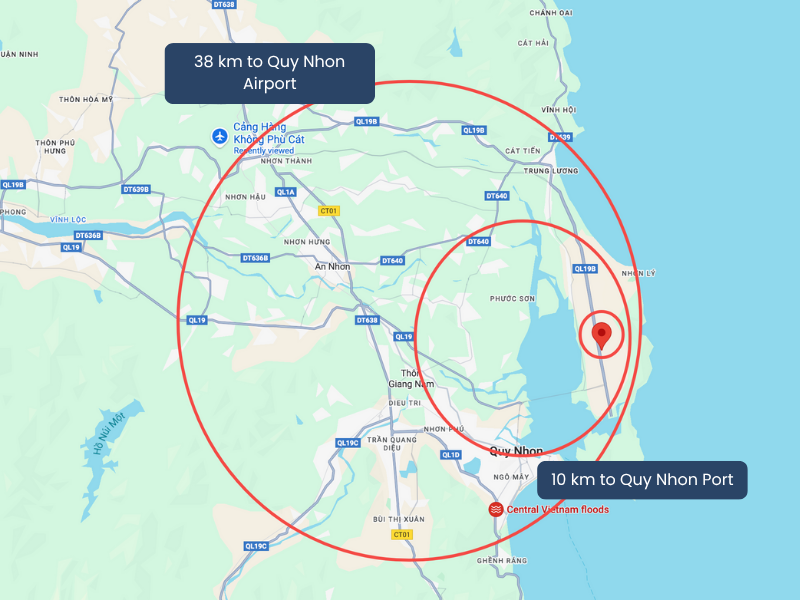

QUY NHON FACTORY

Our new Vietnam furniture manufacturing facility designed for the future of luxury furniture production.

120,000 m² Factory Area

Massive production capacity with dedicated zones for future expansion.

38 km to Quy Nhon Airport

Convenient access to the local airport facilitates easy site visits and logistics.

10 km to Quy Nhon Port

Strategic proximity to the sea port ensures rapid and cost-efficient export.

Construction Phases

Phase 1 (2025)

62,894 m²

Phase 2 (2026)

55,852 m²

Our Work in Luxury Hospitality Spaces

Frequently Asked Questions

Here are some of the questions we often receive from hotel owners, operators and designers.

1. What is the typical lead time for hotel furniture from Vietnam?

Lead time depends on project scale and complexity. For a standard hotel, production usually takes 3 months after final approval of drawings and finishes, plus shipping time.

2. Can you coordinate projects that involve both China and Vietnam production?

Yes. Our central project management team coordinates both China and Vietnam resources, ensuring unified quality and finish across all furniture items.

3. Which ports do you usually ship from?

For Vietnam production, we typically ship from Cang Cat Lai Port and Quy Nhon Port. We can also arrange multi-port loading if your project requires split deliveries.

4. How do you ensure control across large hospitality projects?

We combine China-based engineering oversight with standardized Vietnam production systems, ensuring clear coordination, predictable timelines, and consistent quality from start to finish.

Ready to Elevate Your Hotel Project?

crafted with precision and delivered with reliability.